Jacking Up The Car

By

Steve Chong

andAndy Woo

Created : 980609

Last updated: 980611

A number of different ways have been used by a number of different people to "lift" their cars. Ramps and jacks have been used. And even where to place the jack stands (or not even using jack stands at all) have been debated. What follows is neither absolute nor perfect, but it is something that has actually be used in practice.

Sometimes when working underneath the car, you only need to jack up one end or the other. Described here are ways to jack up both ends either separately, or simultaneously.

Method 1

Jacking up the front

1) Because my car has been lowered, I drive the front tires of my car over two pieces of 2" x 8" wood planks. This allows me to get my jack underneath the front part of the car. Otherwise, I would not be able to slide the jack underneath the front bumper of the car.

2) Slide the jack underneath the front bumper so that the handle of the jack will rise and fall between the front bumper and the front tire. This gives me the 'most' amount of height to raise and lower the jack handle. If you are patient, you can always place the jack in from directly in front of the car.. but then you're limited in a rise-and-fall height of the jack handle to the bottom of the bumper.

3) Place the jack "seat" underneath the suspension cross member. I personally have a 3 ton jack, but I'm one to over-kill on some things! :-)

4) Before I start jacking up the car, I place wheel chocks behind the rear wheels. Hand brake is always on. I place the wheel chocks roughly 1" away from the tire itself, so that

it does not make contact. The reason being, that when I jack up the car, the car has a natural tendancy to roll a little bit. Then I jack up the car to the desired height. Some people need more clearance than others! :-)

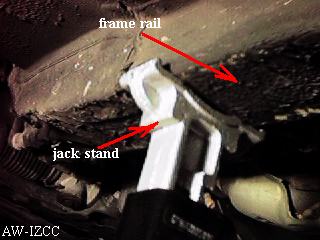

5) Then I place my jack stands on the frame rail that is just to the outside of the fuel rails. This 'frame rail' that I'm talking about... is just inside of the crimped metal that you can feel extending down to the ground. It is where the colored rocker panels meet the underbody metal of the car.

I used jack stands with a rating of 3 tons.

I AVOIDED putting the jack stands on this crimped metal (although I've seen some garages try to do that to other cars, it is not recommended unless you have a piece of wood, or something else that has a slit to allow the crimp to sit in. So that the lift or jack stand puts the weight on either side of the crimp, and not on the crimp itself). Jack stands should be placed on both the left and right side of the car. I never put a stand on only one side of the car. Hate to 'torsion' the car unnecessarily.

6) Then I slowly, very slowly, lower the car onto the jack stands, making sure that I eye-ball it so that the car comes down squarely on the jack stands.

7) Then I move the wheel chocks directly against the tire so that there is no room for play.

Jacking up the rear

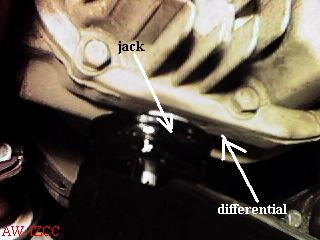

1) I place the jack "seat" underneath the differential.

If the front of the car is already on jack stands, proceed to the next step. Otherwise, I place wheel chocks in front and behind the front tires, about an 1" away from the tire.

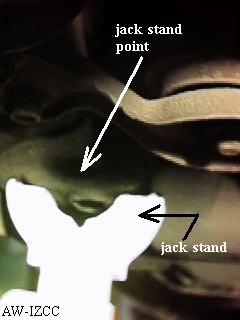

2) I jack the car up to the desired height (some people need more clearance than others) and then place the rear jack stands to a point just in front of the rear tires. It's a point on the car where it seems like the piece has a hole in it.

3) I then slowly lower the car while watching carefully that the car sits down on the jack stands properly.

4) Then I move the front wheel chocks directly against the tire so that there is no room for play.

Note: If my intention is to jack up BOTH the front and the rear of the car up on stands to have the car level in the air. The jack stands in the rear of the car will actually have to be set at a height higher than in front.

How much higher? Uhh..... dunno. Can't remember. But you can tell!!! :-)

Method 2

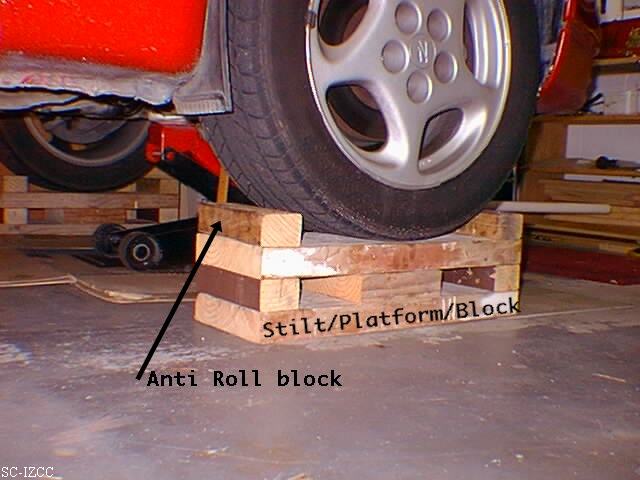

Jacking up the car is done using the same method as #1, however, instead of letting the car's frame sit on jack stands, another method is to create "wood-based stilts/platforms/blocks" for the car's wheel/tires to sit on.

One of the advantages of method 1 is that you dont need a jack with a high lift. Method 2 requires that the jack take up the suspension travel, so you need to have a jack with around 19 inches of lift. A 3 ton jack like this costs about $US100

Here's the car up on all fours. Sitting on top of these home-made wood 'stilts/platforms/blocks'.

Here's a closer look at one of the front 'stands', you can see that pieces of wood have been built at the top of the platform to prevent the car from 'rolling' off the stilt/platform/block. As well, the top surface is lined with a rubber/sand compound to prevent slipping.

There are 2 main advantages of method 2. One is that the platform is really stable, and if you need to use alot of force under the car, you dont have to worry about the car coming off the jackstand. The other is that you can get extra ground clearance when you use the wooden blocks in conjunction with the high lift jack. Perfect for getting leverage on those rusty exhaust bolts, or if you are the portly type. You can get an idea from the two following pictures. Even at these heights, the rig is still extemely stable and wont topple when you put that extra torque on the wrench.

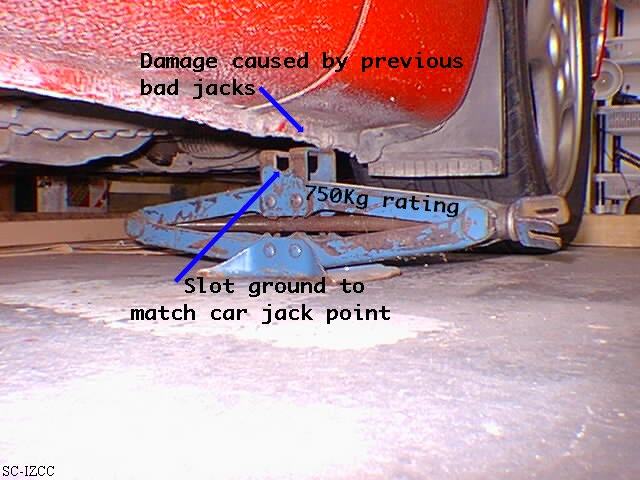

One final matter. As an alternative to driving up on the 2"X8", you might consider a small jack modified to lift the car sufficiently for the 3 ton jack. A modified jack is necessary to prevent damage to the verticals at the recommended scissor jack points. You can see how past owners of the red 91 TT have damaged the verticals by using unmodified jacks.

By the way the 90+ in the picture has a standard suspension, but due to age, has sagged to 4 inches ground clearance at the lowest point (the exhaust system- standard)

Happy jack'ing

Steve Chong and Andy Woo

June 1998