How to install adjustable tension rods

By Jim Morford, II

Let me begin by saying that over time I began to notice a slight tendancy of the car

to pull to the left. After some time, I determined that I would go to have it aligned.

Everything seemed to be okay, except for my caster, which was out of whack. The

alignment gentleman told me that I should go to a frame shop to have it straightened.

This did not strike me as something I wanted to do. Fortunately, with the resources we

have in the IZCC mailing list, I was able to learn that adjustable tension rods were

available to change the caster of the vehicle. I ordered these from Stillen, at a cost of

around $350.

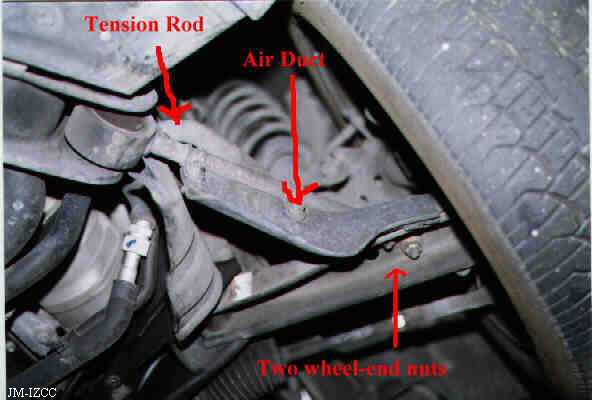

Above we see the Z lifted into the air, exposing the tension rod. The first (and easiest) step

is to remove the air duct. I believe its purpose is to send air into the front brakes for

cooling. Next, you will want to remove the big bolt at the end of the rod. I believe this

is a 17mm bolt, but don't quote me on that. To make your job easier, loosen the undercover

around the end of the rod. These are 10mm screws.

Above is the rod showing a poorly sketched in bolt and the undercover.

Above here you can see the big bolt pulled out slightly. (Tougher than it looks!) This was

enabled by the moving of the undercover slightly. Once removed, that end of the rod is free!

Now, if you'll refer back to the first picture, you'll see two nuts near the wheel. (Forgive

my naming of parts, but I don't know their proper names, so...) Those are also 17mm I

belive. Remove those, and the rod will not be "attatched" to the car, per-se, but you will

need a mallet to pound the bolts out of those holes. When you have the rod free, you will find

that the bolts those two 'wheel end nuts' were on are driven into the tension rod. We placed

the rod in a vice and used an air hammer to drive them out. You see, those bolts are toothed.

Once you have driven the toothed bolts out of the old rod, take the new rod, and try to

adjust it to be the same length as the old one. (As closely as you can.) Then you can begin

to install the new ones. I started by sliding the big bolt at the other end in, so that the

rod could hang from there. Then, I placed the toothed bolts in their proper place. The threads

come through far enough that you can get the nuts started on them. The bolts won't just slide

in, however, because there are no indentations for the teeth.

This is where the air ratchet came in handy. After the nuts were started, we simply "pulled"

the teeth down into the rod, making their own grooves as they went. With 600 ft/lbs. of torque

on hand, the air rachet can do what human hands can't. 8) Anyways, with the two wheel end

nut/bolt combos finished, we can tighten down the big bolt on the other end. Do your best to

replace the loosened undercover again. I found that a few bolts wouldn't go back in no matter

how hard I tried.

Also, replace the air ducts for the brakes. You will find that only one of the clamps will

fit, as the other one would go around part of the new rod that is too large for it. Someone who knew

this ahead of time could perhaps fashion a new clamp that was bigger, and still be able to use both.

Do this on both sides, and hopefully you should have no problems. Take the vehicle to have it

aligned, as you should with any suspension work. Show the alignment gentleman where to adjust

the rods, and he can put it in specs. (9 to 10 degrees). If, for some reason, you can't get them

to move all the way into spec, then set them as close as you can, and evenly. For example, I could

get my left side to 9.2, but the right side wouldn't go past 6 degrees. This would have caused more

pulling and excessive tire wear. As a result, I set them both to 6 degrees, which is as close to

spec. as I could get them both.