Do you want electronic ignition on your 240Z? Don't want to pay through the nose?

Check this out!

Do you want electronic ignition on your 240Z? Don't want to pay through the nose?

Check this out!

The Following write-up was contributed

by: Kyle Hagemann IZCC #968.

You may visit Kyle's Personal Web Site at: http://www.sonic.net/~kyle" for additional information, or e-mail him directly at: kyle@sonic.net

(Last Up-dated 18 Mar. 2001)

This is very easy to do, and total cost is less than most aftermarket

setups. Here's what I spent, roughly:

| Standard GM four-pin HEI module, like the one above |

|

| MSD Blaster II coil (optional) |

|

| Spade lugs for electrical connections |

|

| '76-78 distributor from a 280Z with mounting bracket (important) |

|

| New cap and rotor |

|

| Total cost |

$100.00 |

If you think this is something you're interested in, here's the details.

Here's the source for this article

- Grab a brew (but just one, mind you).

- Take the new distributor cap, and hook the spark plug wires up to it

in the right order.

- Unplug the black wire from the distributor, and remove the adjusting

screw.

- Slide the distributor out, noting the direction the rotor points.

- Remove the mounting bracket. This is the

part that the adjusting screw screwed into. It's held in with two

10 mm head bolts. This must be replaced with the proper mount for

the 280's distributor. If you screwed up and didn't get the mount

from the junkyard, you may be able to modify the stock mount and/or

the new distributor a bit to work.

Check the new

distributor for proper operation. The vacuum and/or mechanical advance

may not work smoothly, so some detail work may be needed. Use your

judgment. Install the new rotor. I've heard a rumor that the

distributors from automatic-equipped cars have an electrical relay that

retards the timing. Hmmm. That could be hooked up to a knock

sensor or a switch inside the car. I'm going to see what I can figure

out about this, eventually....

Check the new

distributor for proper operation. The vacuum and/or mechanical advance

may not work smoothly, so some detail work may be needed. Use your

judgment. Install the new rotor. I've heard a rumor that the

distributors from automatic-equipped cars have an electrical relay that

retards the timing. Hmmm. That could be hooked up to a knock

sensor or a switch inside the car. I'm going to see what I can figure

out about this, eventually....- Install the new mount onto the timing case cover, sealing it with some

gasket goop. Make sure that the hole for the adjusting screw is toward

the front.

- Install the distributor with the rotor pointing in the same direction

as the old points distributor. Snap the cap on, and call it good.

- Down half your brew, and start 'er up.

- After you realize that it won't start because you still have a bunch

of new parts left,

- Make a bracket to hold the module in a position of your choosing.

I used a piece of 1/16" aluminum, bolted to

the lower coil mounting bolt. Drill it as necessary to hold the mod

with two sheet metal screws.

- Here you need to make a choice - are you using an

MSD coil or not? I say MSD Blaster II, but any coil designed for

12V input will work. The important distinction is between a 12V in

and a coil designed to work with a resistor. If you take out the

ballast resistor, but use a coil meant to have one, you will cook

the coil in very short order.... It is possible to use the stock coil,

and I will include stock-type coil instructions in small

type.

- Install the new coil in the same location as stock. Hook everything

up. Some of these connections will be disconnected in a few steps,

but this makes it easy to keep from getting mixed up.

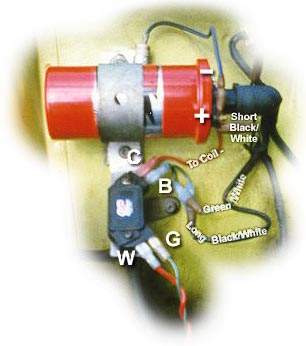

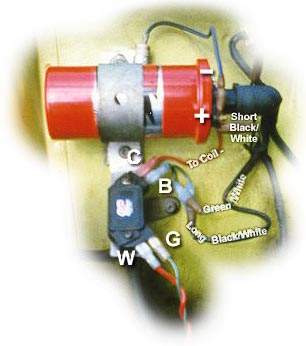

- Take out the ballast resistor. This will leave a green/white

wire and a long black/white wire hanging loose. If you're

keeping a stock-type coil, leave the black/white wire hooked up.

Make a Y-jumper

from a piece of wire. It should have two male terminals and one female.

Connect the female terminal to termial B on the module. Connect one

of the male terminals to the long black/white wire and the other to the

green/white wire. Take another swig - you've made the first electrical

connection. Then again, it's the most difficult connection to make,

so take two swigs. Or, you cheapos can make

a Y-connector with two females and one male connection. The male

connection gets hooked to the green/white wire. Then hook one of

the females to the naked side of the ballast resistor and the other to

terminal B. Got it? That's the only difference between the

two setups....

Make a Y-jumper

from a piece of wire. It should have two male terminals and one female.

Connect the female terminal to termial B on the module. Connect one

of the male terminals to the long black/white wire and the other to the

green/white wire. Take another swig - you've made the first electrical

connection. Then again, it's the most difficult connection to make,

so take two swigs. Or, you cheapos can make

a Y-connector with two females and one male connection. The male

connection gets hooked to the green/white wire. Then hook one of

the females to the naked side of the ballast resistor and the other to

terminal B. Got it? That's the only difference between the

two setups....- There should be a black/white wire connected to the + side of the coil,

and another from that terminal to the noise-suppressing capacitor above

the coil. Leave them alone!

- There's a plain black wire connected to the - side of the coil.

Disconnect it, and make a jumper to connect terminal C on the module to

the - side of the coil.

- Attach a female connector to the + wire from the distributor (it should

be a red one). Connect it to terminal W on the module. By the way,

I've heard that some distributors have two green wires. To determine

polarity, Andy Levy says this can be done by rotating

the dist. shaft the same direction as it would be turned by the engine

and use a volt meter to establish the polarity. This system generates

AC current so look for a positive reading when the raised portion is

approaching the pick up and negative when it departs.

- The final connection is from the G terminal on the module to the negative

wire on the distributor. That should be a green one.

- Bolt your module mounting bracket to a convienient location and screw

the module into it. Be sure to use the included grease.

- Start it up, set the timing, and road test it.

- Everything satisfactory? Finish your adult beverage, likely very

warm and disgusting by now, and congratulate yourself on a job well done!

Another thing that might help is a good understanding

of how the stock system works in comparison to the HEI. If you prefer

simple how-to instructions, and don't really care why, skip this part.

Got your thinking cap on?

In the stock setup, you have a solid black wire that

runs from the coil - to the points. The points close as the dist.

turns, completing the circuit. On the + side of the coil, you have

a short black w/white wire. That wire is hooked up to two others

under the electrical tape. One is the longer black w/white wire connected

to the resistor. The other is a wire that feeds 12V+ to the coil

while cranking, bypassing the resistor. The other side of the resistor

is connected to a green w/white wire, which supplies 12V+ during normal

operation. The reason for the cranking-position 12v+ feed is that

during cranking, power is cut to other sources, like your radio.

Still with me?

Anyway, the HEI setup is really simple. It gets

its ground by one of the mounting screws, which is switched on and off

to the module's terminal C. Terminal C, in turn, is connected to the -

side of the coil. This is the same as the stock setup then, because

the points open and close the ground side of the primary coil circuit.

The + side of the coil gets juice all the time, just like the original.

It's hooked up to the balast resistor OR 12V+. If you've got a 12V

input coil (MSD Blaster II), the + side of the coil is connected directly

to the module's terminal B. If, on the other hand, you have a stock-type

coil, the input side of the balast resistor is connected toterminal B.

Got it? The other two terminals (W & G) on the module are connected

to the + and - inputs from the distributor. On my dist., the + is

red, the - green. If your dist. doesn't have the same colors, it's

simple enough to figure out. The scoop was above, remember?

Here's the theory, as I understand it: The dist.,

as it goes round, generates small voltages, which are sent to the module.

The module then opens and closes the primary coil circuit based on these

signals, in some high-tech solid state way. The key here is solid

state. No moving parts, nothing to wear out, adjust, or replace.

Cool huh?

Did I screw something up? Forget to credit your

part in this saga?  Tell

me!

Tell

me!

Do you want electronic ignition on your 240Z? Don't want to pay through the nose?

Check this out!

Do you want electronic ignition on your 240Z? Don't want to pay through the nose?

Check this out!

Check the new

distributor for proper operation. The vacuum and/or mechanical advance

may not work smoothly, so some detail work may be needed. Use your

judgment. Install the new rotor. I've heard a rumor that the

distributors from automatic-equipped cars have an electrical relay that

retards the timing. Hmmm. That could be hooked up to a knock

sensor or a switch inside the car. I'm going to see what I can figure

out about this, eventually....

Check the new

distributor for proper operation. The vacuum and/or mechanical advance

may not work smoothly, so some detail work may be needed. Use your

judgment. Install the new rotor. I've heard a rumor that the

distributors from automatic-equipped cars have an electrical relay that

retards the timing. Hmmm. That could be hooked up to a knock

sensor or a switch inside the car. I'm going to see what I can figure

out about this, eventually.... Make a Y-jumper

from a piece of wire. It should have two male terminals and one female.

Connect the female terminal to termial B on the module. Connect one

of the male terminals to the long black/white wire and the other to the

green/white wire. Take another swig - you've made the first electrical

connection. Then again, it's the most difficult connection to make,

so take two swigs. Or, you cheapos can make

a Y-connector with two females and one male connection. The male

connection gets hooked to the green/white wire. Then hook one of

the females to the naked side of the ballast resistor and the other to

terminal B. Got it? That's the only difference between the

two setups....

Make a Y-jumper

from a piece of wire. It should have two male terminals and one female.

Connect the female terminal to termial B on the module. Connect one

of the male terminals to the long black/white wire and the other to the

green/white wire. Take another swig - you've made the first electrical

connection. Then again, it's the most difficult connection to make,

so take two swigs. Or, you cheapos can make

a Y-connector with two females and one male connection. The male

connection gets hooked to the green/white wire. Then hook one of

the females to the naked side of the ballast resistor and the other to

terminal B. Got it? That's the only difference between the

two setups....