Dropping a 1981-83 L-28

motor into a 240Z, with 5-speed and 3.90 differential (back)

It's important to know that externally, all '70-83 motors are identical,

only the bore and stroke are different. This is why swaps are so easy.

And not only does the extra torque from the 2.8 liter motor move the car

much more quickly, but this gives you the chance to upgrade the transmission,

differential and drivetrain to better, stronger 280Z parts. I like a 3.90

rearend, but you can leave the stock one in. Keep in mind that all 280Z

engine and drivetrain parts retrofit into the 240Z.

FIRST -the motor

Locate a '81-83 motor in a junkyard. Check the

cylinder head between the 1st and 2nd spark plugs to find the cylinder

head code. "P-79" is what you want.

- The P79 and P90 head were designed by the factory

for high-flow turbo applications and the block has flat-top pistons

instead of the dished types on '75-80 motors. This means all combustion

is confined to the high-swirl combustion chambers, which provides a more

controlled quench-and-burn than a dished piston allows. In addition, the

compression is 8.8:1 compared to the '75-80 motors which had a low 8.3:1

for good emissions. Tolerances are tighter and more consistent than earlier

motors too. And while many people argue that the '75-76 head/motors are

superior, I think that's because they quote from the "How to Modify

your Nissan OHC", by Frank Honsowetz. Had it been written in 1988

instead of 1978, I'm sure he would have recommended the P-79 instead of

the N-42 or N-47. BTW, the 170 horsepower stated for '75-78 motors is GROSS

horsepower instead of NET, which means those motors really have a NET of

135hp vs the P-79's 145hp. I can get a P-79 motor for $79.95 at my local

salvage yard, and I feel the the best ones are in automatic transmission

cars. Because of lower shifting points, the engines are probably less abused.

But make sure you get a manual transmission flywheel and the rear sandwich

plate from a manual transmission car.(see below).

- LUBE TIP: I was told by my friend the Z Doc that straight

30-weight oil should be used in L series motors. He said Mobil 1 was his

first choice, then 30 weight, then 10W-30. He felt that a straight viscosity

was more "stable" than a multi-viscosity which has more polymer

additives. In deep cold he recommended going to a 10w-30. I have heard

from more than a couple of engine rebuilders over the years that Castrol

was the best out there, so I'm running GTX 30W. Works for me...

SECOND -the transmission

- Locate a junkyard '77-79

280Z five speed tranmission. While It's ratios are "taller"

than a stock 240, coupling it with a higher-ratio

differential will provide greater acceleration and superior shifting.

But DON'T use a '80-83 5-speed with

any rear-end higher (lower numerically) than a 3.90. This trans has the

highest ratios and will slow acceleration in all gears if a 3.36, 3.55

or 3.70 is used. Just remember to get the sandwich plate from between trans

and motor on a manual trans if you use a motor from an auto trans car.

The automatic's plate only covers the top half of the trans, while the

manual's goes all the way down.

- On a junkyard 3.90 280ZX, follow the speedo cable into the side

of the trans, and remove the speedo cog and sleeve. This has a white plastic

cog (3.90) which must be exchanged for the black cog in the '77-79 (3.54)

trans to keep the speedometer correct. But, you HAVE to swap the white

cog with the black one on the older sleeve.Using the newer sleeve in the

older trans won't work, the sleeves are physically different and the newer

one won't let the cog mesh with the gear in the older trans. It's easy

to swap the cog, just drive a small pin out.

- On early 240's, you may have to cutout about 2 inches of metal

from the front edge where the shifter goes through the trans tunnel. A

5-speed sits forward slightly and the gearshift may requires more clearance.

This cutting is the price of a 5-speed trans. If this really stresses you,

install a ZX 5-speed. Supposedly they don't require cutting.

THIRD -the flywheel and clutch

- There are 2 versions of flywheels on all '75-83 motors, standard

and 2+2/turbo. About 23 lbs each.

- Standard and 2+2 clutches aren't interchangable because the bolt

holes don't match with the flywheel's.

- If you have an automatic transmission engine, make sure you get

a flywheel from a manual trans car to take the place of the auto-transmissions's

"drive-plate".

- A pilot bushing also needs to be installed in the crankshaft if

using an auto trans motor (they didn't get one).

This

is my 2+2 flywheel and clutch. Click on it (34K)

This

is my 2+2 flywheel and clutch. Click on it (34K)

Measure the width of your flywheel's shiny clutch contact surface.

If it's 225m wide then you have a standard flywheel. 240mm means you have

a 2+2 version. This lets the standard 280 use a 550lb pressure plate while

the 2+2 uses a 780lb with a wider disc. So you're lucky if you have a 2+2

flywheel because you can use the stronger 2+2 clutch. But make sure the

"collar" holding the throwout bearing matches the flywheel (standard

vs 2+2) or the clutch-fork angle will be off. I had to scavange a 2+2 collar

from the junkyard because my trans came from a standard car, but my motor

had a 2+2 flywheel.. So note which flywheel the car you get the trans

from had, so you can matchup the right clutch and throwout bearing collar

(Motorsport Auto has collars for a few bucks). Remember, all motors and

throwout bearings are the same, but order the clutch and collar to match

the flywheel type your engine has, then the year transmission. EXAMPLE: "

I need a complete clutch for a 1977 280Z, 2+2" (even if you have a

'81-83 motor).

FOURTH -the differential

Check out

the size difference between a R200 (left) and R180 (28k)

Check out

the size difference between a R200 (left) and R180 (28k)

Get the R-200 differential out of a junkyard '81-83 NON-turbo

ZX . This will have a 3.90 ratio ('81-83 turbos had a 3.54) compared

to the 3.36 in the 240 and 3.54 in the '75-78s. Some 280ZXs had a R180

rear like the 240Z, make sure you don't get one of those by mistake. Since

the entire 280Z rear end will tranplant into a 240, offer them $100 for

the whole rear-end and see if they bite. Talk about a wolf in wolf's clothing.

Grab these parts:

- the curved rear crossmember which bolts immediately behind the bottom/rear

of the differential (early models are straight).The R-200 sits back by

about 1 1/2 inches and needs the curve. Bolts in perfectly.

- Get the "mustache bar" that bolts onto the rear differential

cover from a '75-78. Despite your budget, replace the bar's bushings with

urethane ones. I actually replaced them with new softer stock ones, which

allowed the extra torque from the 3.90 to twist the bar-ends and "thunk"

them against the floor. A waste of money. But this made me realize that

thunks are not always caused by the front mount.

- Get the R-200 halfshafts too. Be careful not to swap the halfshafts

as the shaft that slips into the differential on the passenger side is

1/4 inch longer than the driver side. I made this mistake and got 2 short

(left) ones from the junkyard. The right one wouldn't "click"

in. Had to go back to the junkyard to get a right-side one. Get the newest

ones possible (less wear obviously. Better tolerances too?)

- Get a good driveshaft from a '76-78 280Z. They are about 20 cm longer

than the 240 shaft, which will maintain drive-angle geometry. Strangely,

'75 shafts were 10mm shorter and fatter and the rear bolt pattern doesn't

fit onto a later R-200.

- The front differential crossmember from a 280Z is thicker and beefier

and should be replaced also. Of course you should replace the front differential

mount with a '75-78 version.

- My '70's differential strap sits forward by about 2 inches compared

to a 280. This let the strap sit directly over the R-200's front mount

nuts on the top, making bolt-up impossible. I had to reverse the bolts,

place the nuts on the bottom, and saw off the protruding bolt threads.

This let me raise the differential with my floor jack, and place it very

tightly against the strap. I mean it's very tight, my front

mount isn't even flexing.

FIFTH -the fuel system

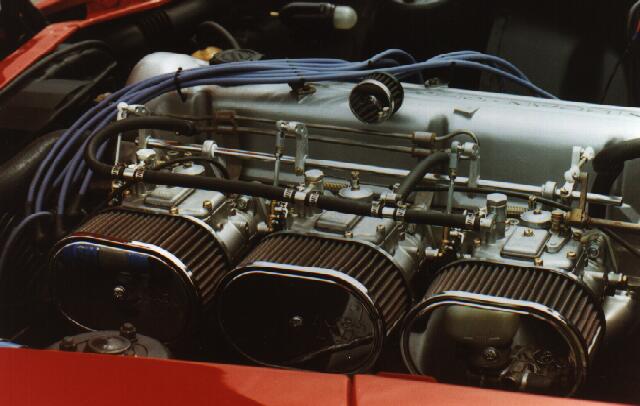

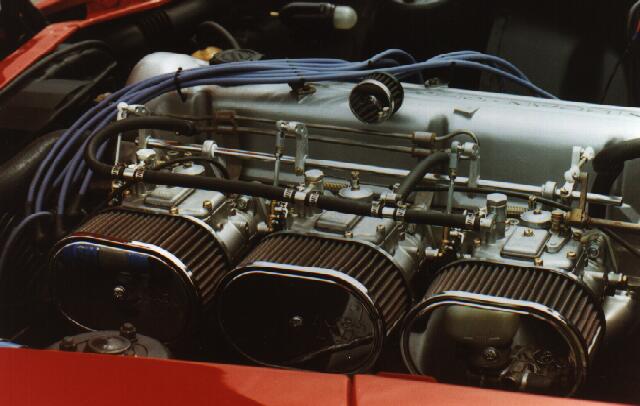

My dream...(42k)

My dream...(42k)

Well, you need fuel at this point, but I can't help you if you

want injection. I use a set of '71 carbs and intake I got in a junkyard

280Z in 1995 for $75, which work perfectly on my '83 motor with no changes.

The carb intake will bolt right up with a '81-83 gasket, but I did have

to hold the intake in place as it's lack of real bolt holes allows it to

shift around when tightening.

- Retain the water cooling through the intake manifold and don't block

off the PCV valve hoses. I used a breather on my valve cover, but it's

important that the crankcase be vented to the intake so the motor stays

clean.

- Keep the stock fuel return rail and use an aftermarket electric

fuel pump with 3-5 psi, Higher pressure can force crud through the filter,

lower causes the bowls to run dry on heavy acceleration.

- Also run the tank vent hose to one of the carbs, otherwise the car

may reek of gas.

- Stay away from the auto-store Purolator electric pumps. Excellent

reliability I'm told, but very noisy. I tried 2 but both had a powerful

ratchetting sound, very audible over my exhaust at idle. Purolator told

me that was "normal", so back it went to Advance Auto. I'm using

a stock VW/Porsche electric fuel pump that was on my car when I bought

it.

According to Motorsport Auto, stock 240Z carb needles will work fine

on a L28, even with a cam. I've checked my plugs and they look perfect,

nice and tan. SM series needles can be used to richen the mixture, if you

can find them.

SIXTH -the distributer

If you want to use the stock 240 distributer, you will need to

add a 280 support available from the dealer or Motorsport Auto (800-633-6331)

to raise it's height. But obviously you're doing this for performance.

SO...

- throw the obsolete, stock distributer in the closet.

- get a junkyard 280Z '77-78 single pickup electronic distributer

(D6F4-03)

- convert it to a super-accurate 45,000volt Chevy HEI/MSD

Blaster coil setup. It connects easily to stock 240Z wiring

without any cutting, and provides phenominal performance. Contact Andy

Levy at allevy@oboe.aix.calpoly.edu

who developed it and turned me onto this killer mod.

- If you want to use a 280Z tach with a stock distributer, connect

the tach's rev sensor directly to the negative post on the coil. If the

tach jumps around, solder a 6.8k ohm resistor inline with the sensor feed

wire. 280's use a similar resistor inline as 280 tachs apparantly need

a lower sensor-input voltage (app. 5V). But make sure you leave the stock

tach's "loop" harness connected, otherwise the car won't start.

Other than these tips, the L-28 is a direct boltup. My 1970 with P79

motor, header and 2 1/4" pipe, SU's, HEI ignition, 3.90, '78 5-speed,

and Crane cam runs consistent hand-timed 0-60's

in 6.6 seconds and a 60-80 in 3.7 seconds in third. It's torque is great

and it revs past redline without hesitation. I'm estimating about 190 horsepower.What

a rush...

Thanks to GEOCITIES for this page.

Check them out.

My

rebuilt P-79 with '71 SU's and 6-2 header. Check out another view (34k)

My

rebuilt P-79 with '71 SU's and 6-2 header. Check out another view (34k) My

rebuilt P-79 with '71 SU's and 6-2 header. Check out another view (34k)

My

rebuilt P-79 with '71 SU's and 6-2 header. Check out another view (34k) This

is my 2+2 flywheel and clutch. Click on it (34K)

This

is my 2+2 flywheel and clutch. Click on it (34K) Check out

the size difference between a R200 (left) and R180 (28k)

Check out

the size difference between a R200 (left) and R180 (28k) My dream...(42k)

My dream...(42k)