Well, after describing my car to the general public for so long, it seems that I have forgotten what a technical group ya'll are. Having been severely chastised by several Z'ers (even over the Internet) who wanted more info, we're going to revisit the engine and drivetrain again:

From the beginning, air enters through an oval K&N air filter mounted just

behind the front bumper (Corky indicated that in his testing, he found it

very important (hp wise) to have the intake out front in cold, clean air),

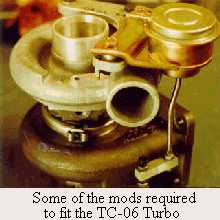

through a 2 1/2" intake tube to a Mitsubishi TC-06 turbo. The turbo was

modified by Corky to fit the stock turbo exhaust manifold.

The bolt pattern

was the same, but he had to add a spacer, remount the wastegate and re-clock

the intake and exhaust housings for proper orientation. The turbo, which has

an integral wastegate and is water-cooled, is one size larger than the TC-05

unit used on the 2.6 liter Starion. When we first started the kit, there were

only two versions of this turbo available. This has turned out to be a popular

unit, as there are over 25 versions of this turbo now with specialized

compressor wheels also available. (Future upgrades will probably consists

of a balanced and blueprinted high-output 'Sport Turbo' of the same series.)

The bolt pattern

was the same, but he had to add a spacer, remount the wastegate and re-clock

the intake and exhaust housings for proper orientation. The turbo, which has

an integral wastegate and is water-cooled, is one size larger than the TC-05

unit used on the 2.6 liter Starion. When we first started the kit, there were

only two versions of this turbo available. This has turned out to be a popular

unit, as there are over 25 versions of this turbo now with specialized

compressor wheels also available. (Future upgrades will probably consists

of a balanced and blueprinted high-output 'Sport Turbo' of the same series.)

Mounted on the outlet pipe, just 6" from the turbo, is a compressor bypass valve. This unit reduces 'turbo lag' and wear on the turbo by dumping or 'bypassing' boost pressure during rapid throttle closings (as in shifting while under boost). Plus it makes a great whooshing/howling/hissing noise between gears! The plumbing then goes forward to a special high-efficiency Cartech intercooler. I even paid extra to have an additional 'half core' added. This brought it up to the same size as normally used on a turbocharged 5 liter Mustang! Pressure drop is critical, and I wanted to have as much cooling capacity as possible to have adequate capability for future upgrades. From there air travels back to a Webber 'Big Throat' throttle body attached to a stock manifold.

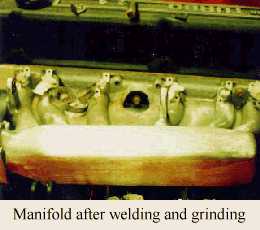

Although the intake manifold looks aftermarket, it is actually a stock intake

from a turbo engine (the turbo manifold actually has 17% larger runners!).

I measured all the different manifolds, and found that the stock non-turbo

FI manifolds are about 2mm smaller than the intake ports in the head. (I

have a feeling Nissan did this to improve low rpm torque and fuel economy.

I also believe these long narrow ports are part of the reason that the 280's

seem to run out of steam around 5500 rpm). Using the turbo manifold, I cut

and ground off all ports, bosses and nipples. Corky welded up the holes and

I kept grinding until the surface was perfectly smooth. I spent over 25 hours

grinding and sanding on it before it was powdercoated. It was also ported to

match the 'Big Throat' throttle body, and all internal projections were ground

off. To keep the 'clean look', all vaccume sources are were accessed from the

bottom of the manifold using aircraft quality steel braided hose.

Although the intake manifold looks aftermarket, it is actually a stock intake

from a turbo engine (the turbo manifold actually has 17% larger runners!).

I measured all the different manifolds, and found that the stock non-turbo

FI manifolds are about 2mm smaller than the intake ports in the head. (I

have a feeling Nissan did this to improve low rpm torque and fuel economy.

I also believe these long narrow ports are part of the reason that the 280's

seem to run out of steam around 5500 rpm). Using the turbo manifold, I cut

and ground off all ports, bosses and nipples. Corky welded up the holes and

I kept grinding until the surface was perfectly smooth. I spent over 25 hours

grinding and sanding on it before it was powdercoated. It was also ported to

match the 'Big Throat' throttle body, and all internal projections were ground

off. To keep the 'clean look', all vaccume sources are were accessed from the

bottom of the manifold using aircraft quality steel braided hose.

Now to the engine; The actual engine mods will probably be disappointing to those of you looking for something trick. The block is a new '82 turbo (L28) with stock (cast) pistons, rods and crank. The lower end has never been apart. I did "O"-ring the block to keep head gasket in place during any detonation that may take place during tuning or testing. I used Isky Racing's O-ring cutting tool and .040" copper wire.

The head is also an '82 Turbo (P90) with stock cam, valves and springs. It has been milled .080" to raise compression from a stock 7.4:1 to around 8.5:1. After adding 5 'headsaver' shims to the cam towers to regain chain tension and valve timing, I had to install 0.170" lash pads (nearly the largest that will fit into a stock retainer) to get rocker arm wear patterns back in spec. The combustion chambers and exhaust ports were polished to a near mirror finish (but not ported), and I left the intake ports basically alone to promote turbulence and keep the fuel in suspension. The manifold and head have not even been port matched yet, although I might do this if I decide to get the intake Extrude Honed some time in the future.

The exhaust is currently a straight-through 2 1/2" pipe with NO muffler.

It is not all that loud at idle and while cruising (the turbo breaks up

the exhaust pulses), but really sounds good under load. It actually has

a rather unusual European V8 growl to it...

The exhaust is currently a straight-through 2 1/2" pipe with NO muffler.

It is not all that loud at idle and while cruising (the turbo breaks up

the exhaust pulses), but really sounds good under load. It actually has

a rather unusual European V8 growl to it...

All other components in the engine compartment have been replaced with new factory pieces. I wanted to start with a good baseline to work from. As part of that, I used the 280ZX starter which is a gear reduction unit and much stronger than the non-reduction design.