The Swap - Page 2 of 4

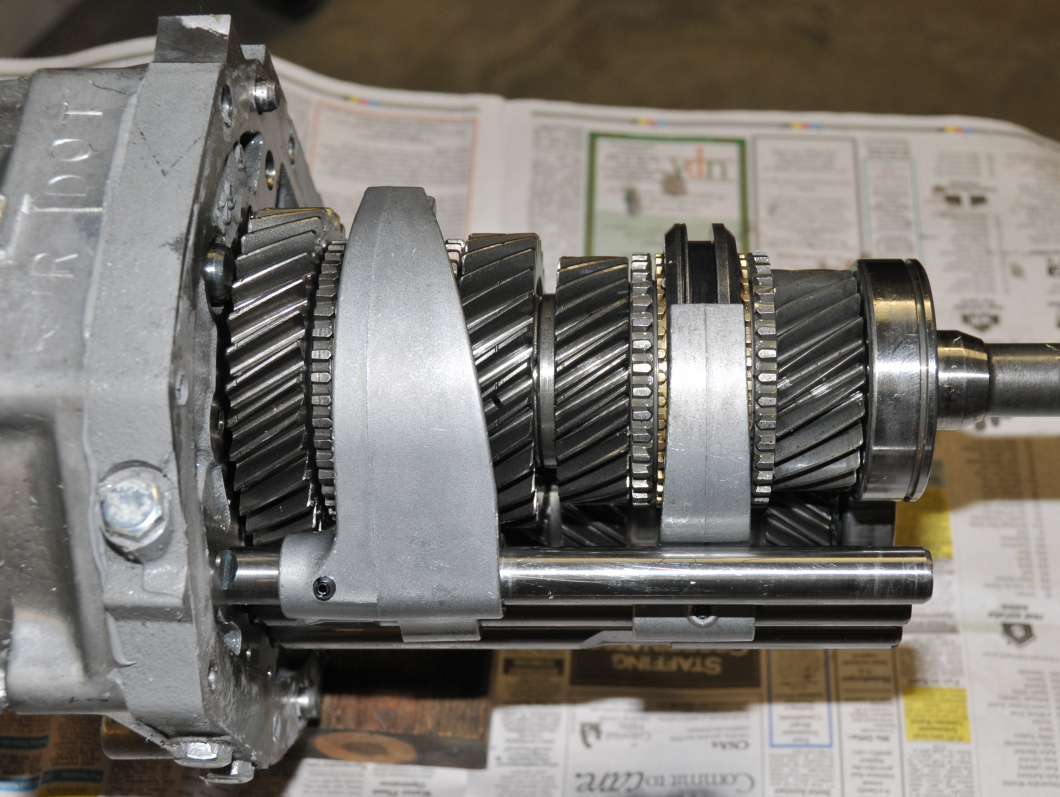

For both B and C transmissions, disassembly consists of:

- Drain the oil and remove the reverse switch

- Remove the throw-out bearing and clutch fork

- Unbolt the front bearing cover and remove it

- Remove the input shaft bearing snap ring

- Remove the case bolts and tap the bell housing forward off the transmission

When I do this, I gently set the transmission on end so that the bell housing is resting on 2 2x4s with the tail shaft pointing up. When I have the case bolts out, I lean the transmission over and place another piece of 2x4 in the middle under the input shaft. Then I lower the transmission until the tip of the input shaft is resting on the piece of 2x4 supporting the whole assembly balanced on the input shaft. I then tap down around the bell housing until it drops away.

Chapter from

service manual

F4W71B

FS5W71C

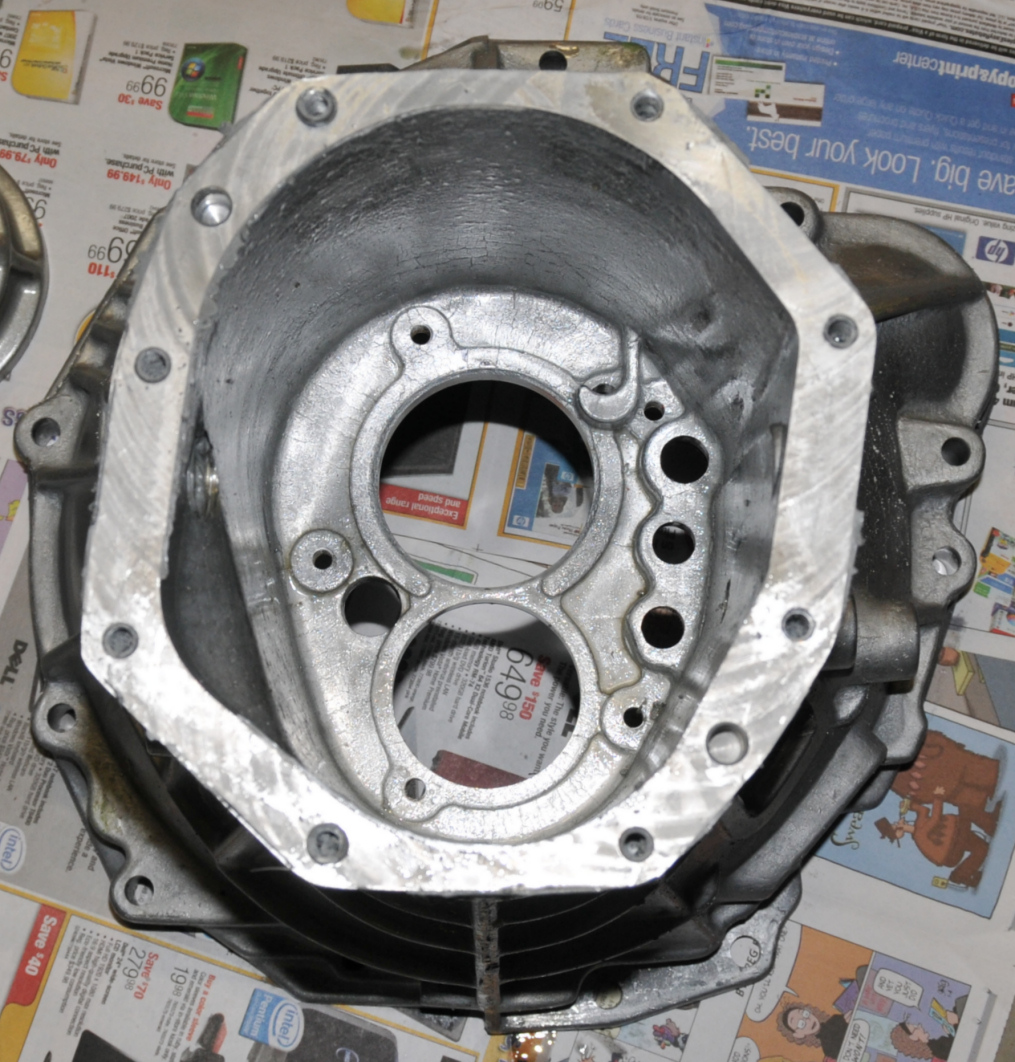

Bell housing

modifications

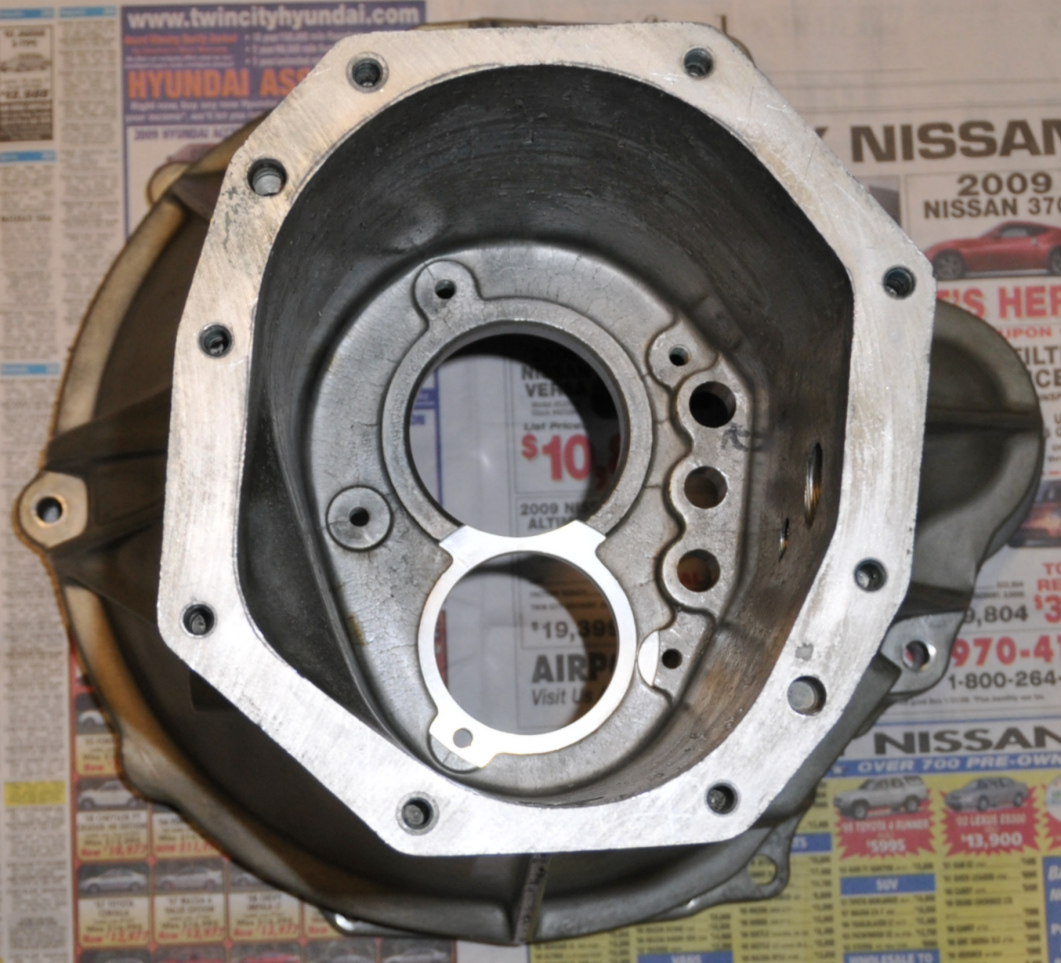

The 71B bell housing needs a few

modifications in order to fit the 71C transmission.

-

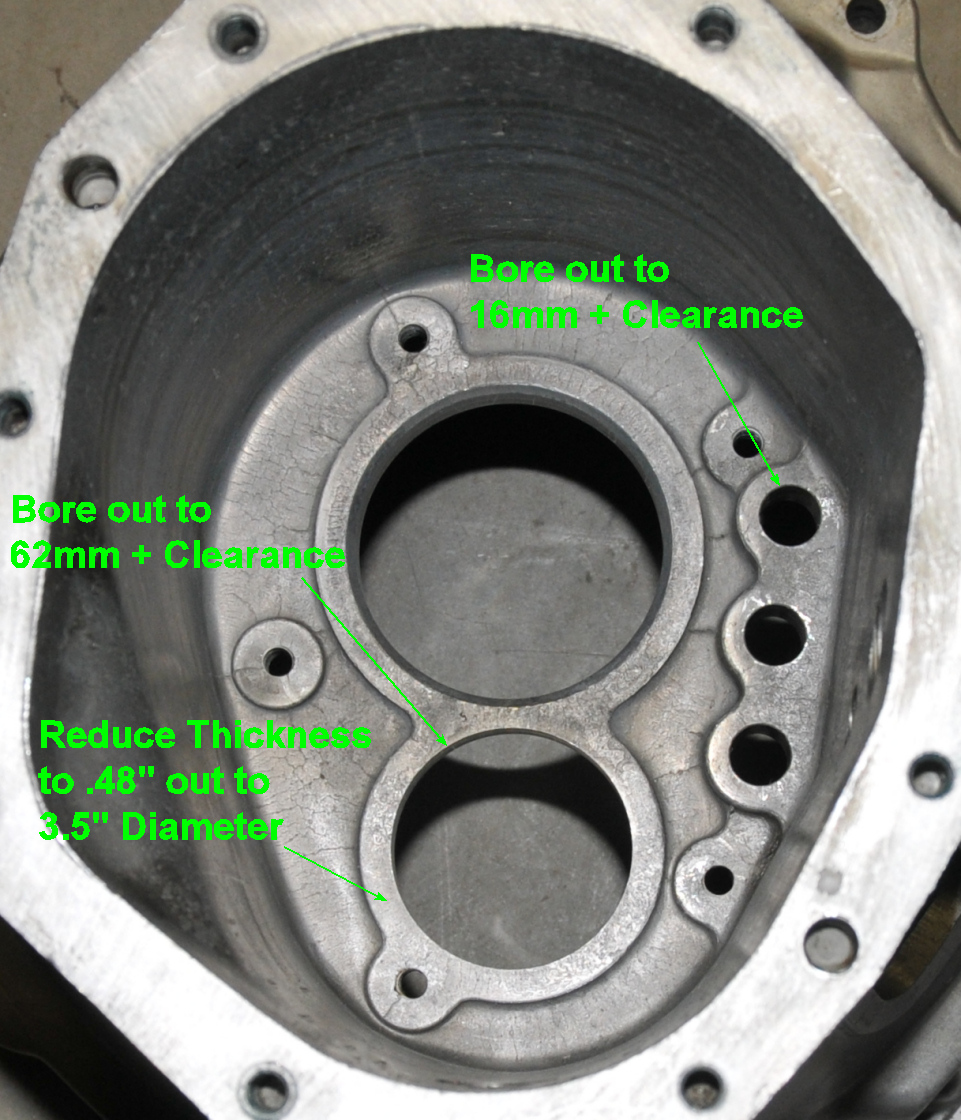

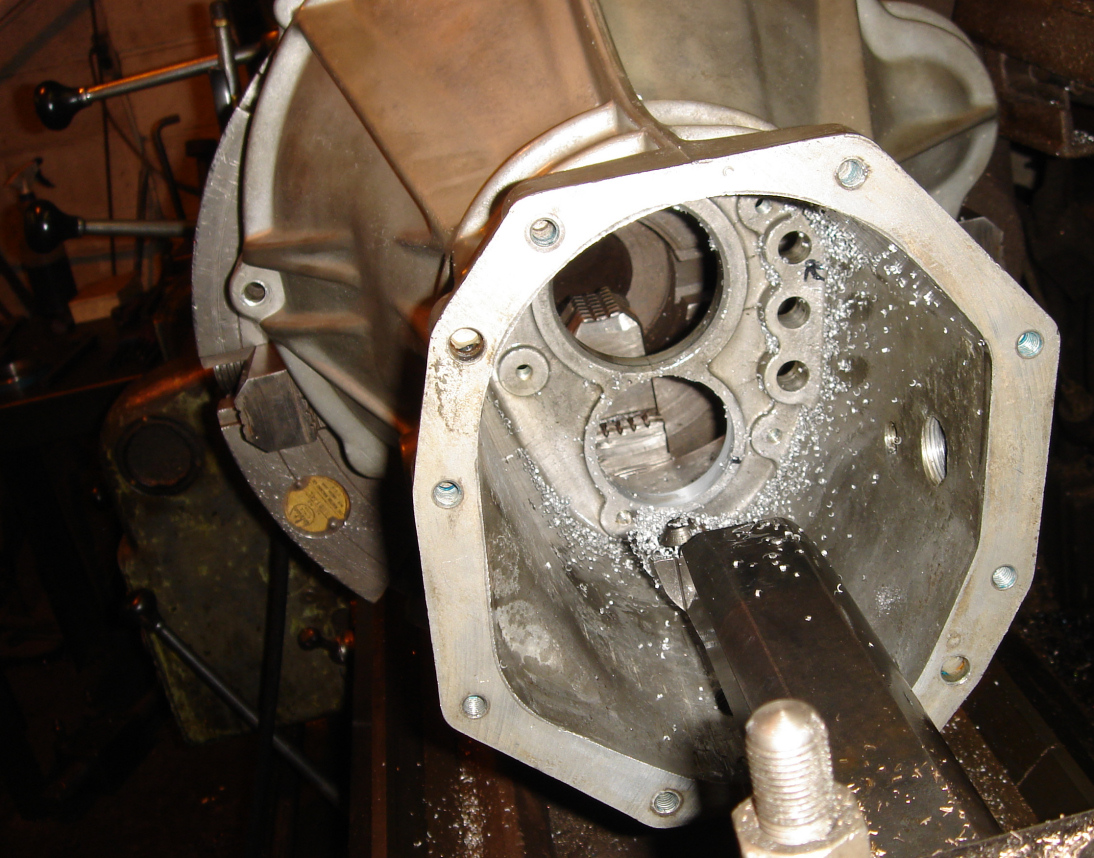

The 1 - 2 shift rod on the 71C was increased from 14mm to 16mm. The

top shifter rod hole needs to be opened up to just over 16mm. I told the

machinist to duplicate the hole in the 71C bell housing

but later had to ream the hole slightly larger myself with an adjustable reamer

because it was too tight.

-

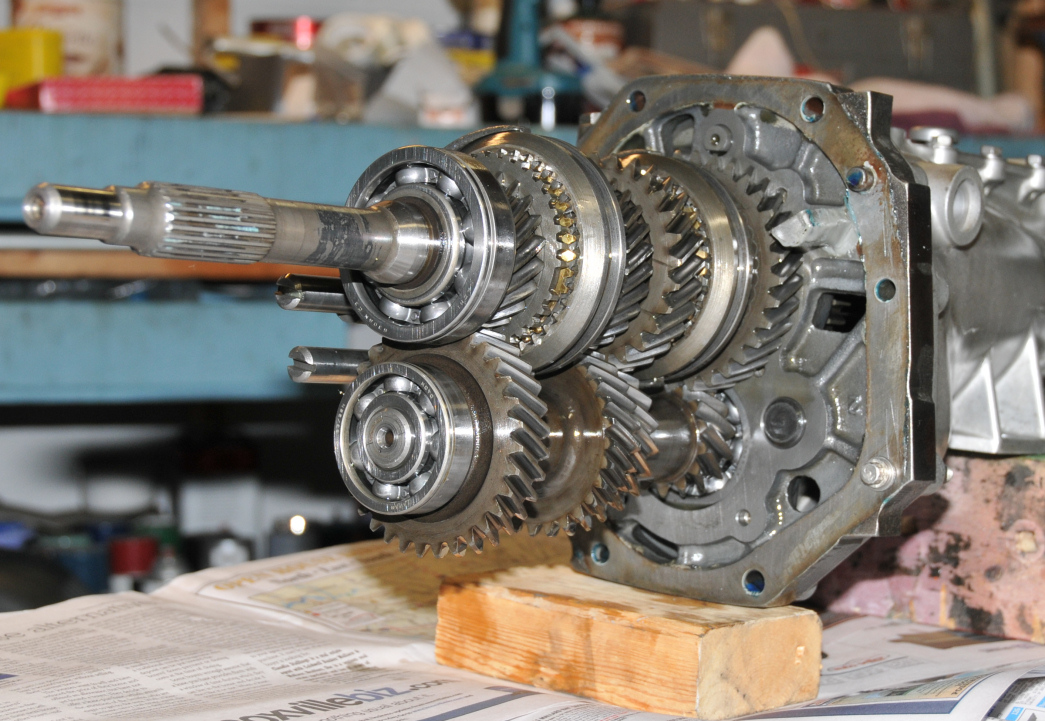

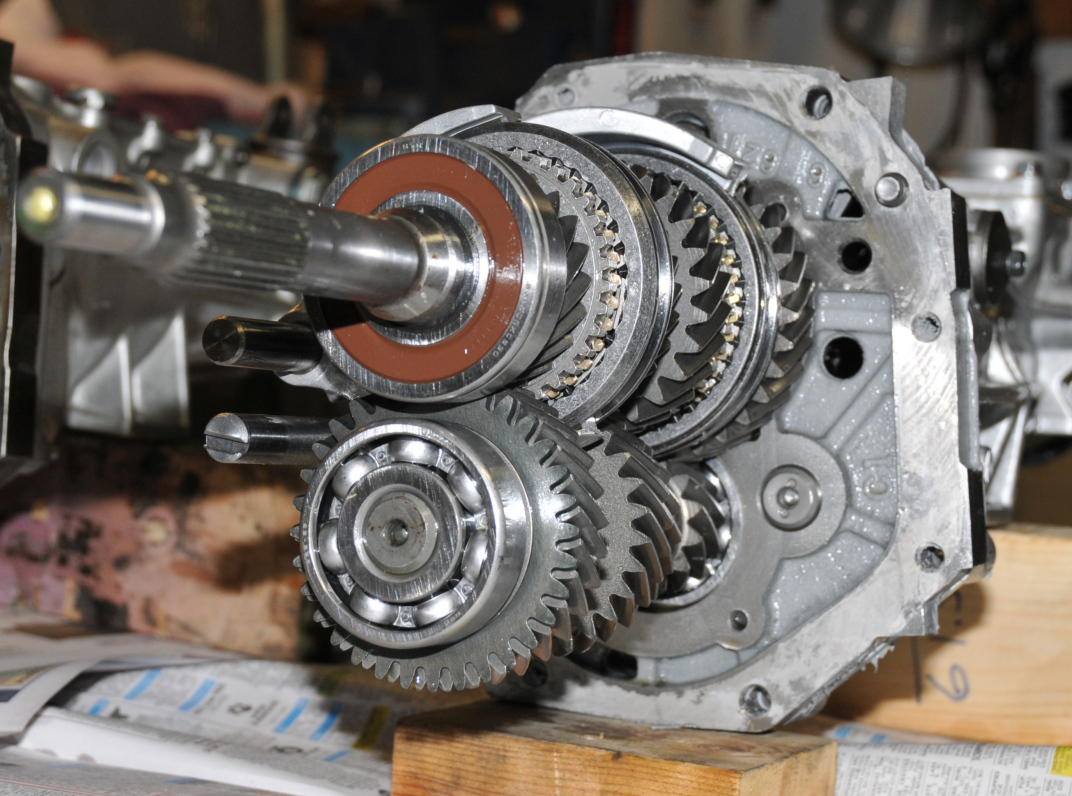

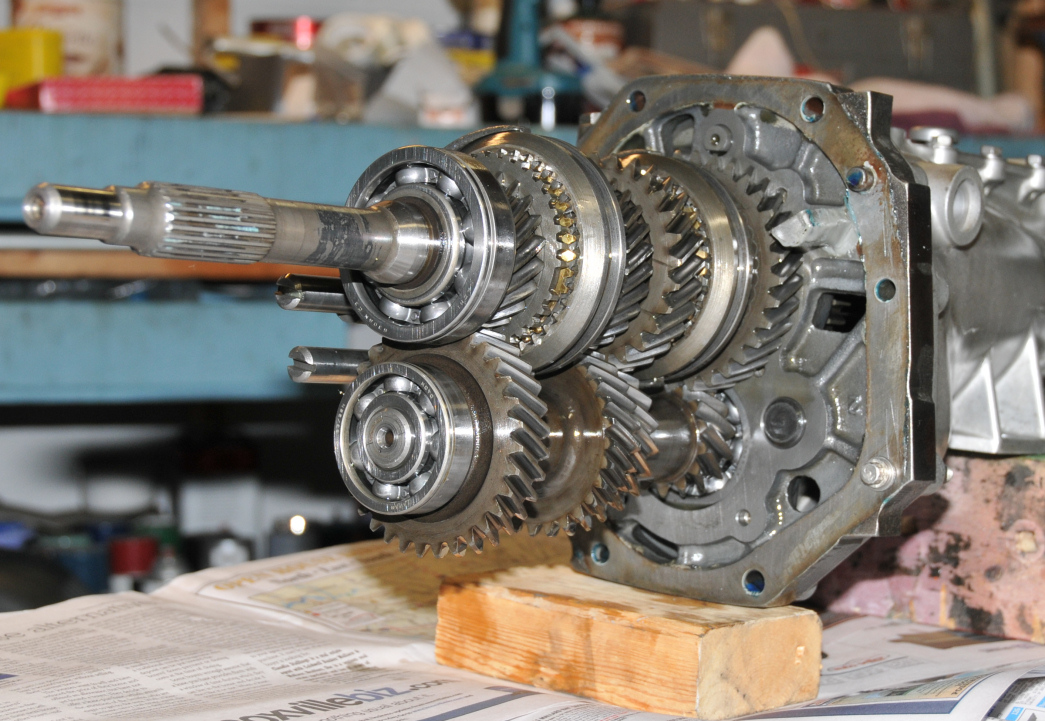

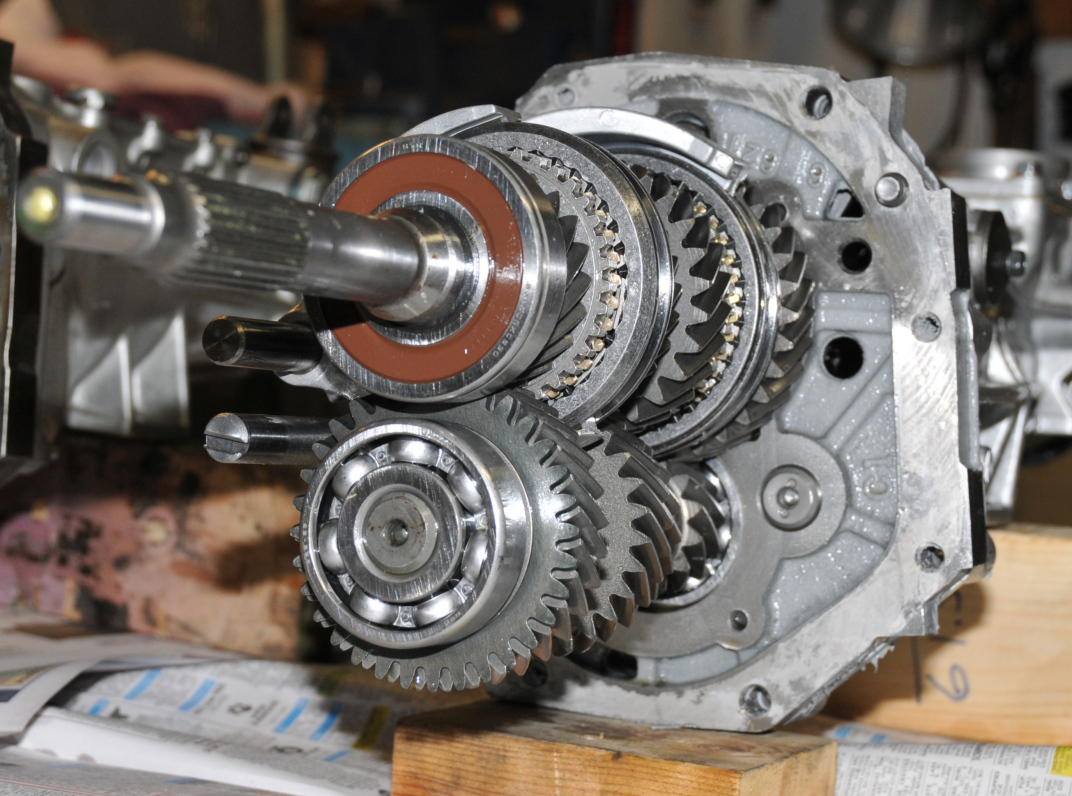

If you want to use the

larger 71C counter shaft bearing like I did, you have to have the lower bearing

hole increased from 56mm to 62mm. Again, the hole needs to be slightly over

62mm to allow the bearing to be a snug, slip fit. You don't want to have

to drive it in with too much force since it has to be pushed in by the counter

shaft pushing on the inner race during assembly. The bearing can be damaged if too much

force is transferred through the roller balls to the outer

race.

-

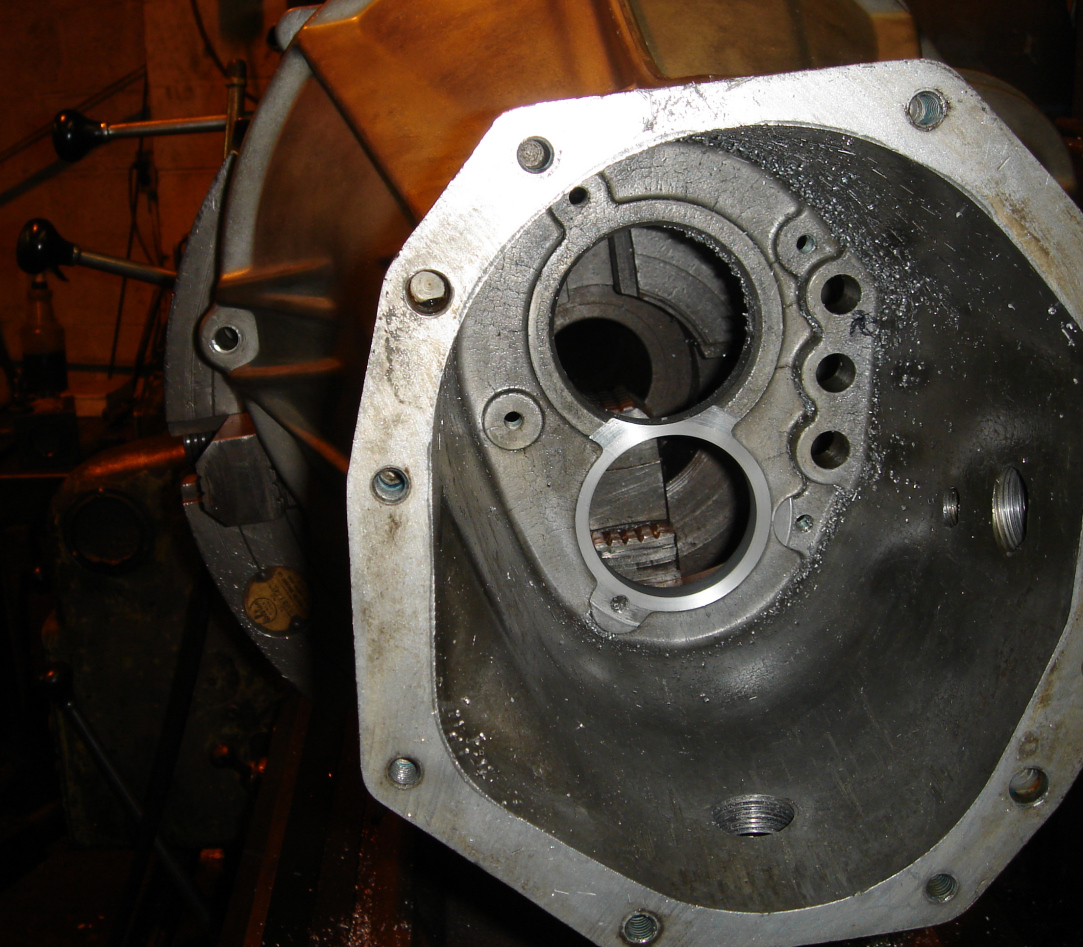

Even if you decide to use the 56mm counter shaft bearing from the 71B transmission, the inner case surface around the counter shaft bearing hole needs

to be relieved to allow clearance for the counter shaft driven

gear. Both the driving and driven gear for the counter shaft are thicker (longer?).

The driving gear (on the input shaft) is no problem because it

is smaller in diameter than the input shaft bearing. The counter shaft driven gear

on the other hand, will contact the area around the bearing so this

needs to be machined to reduce the thickness out to a diameter of about 3.5"

or just remove the raised boss around the hole. The thickness in this

area was .61"on the 71B, but only .48" on the 71C (about .13" difference). I

had the machinist duplicate the 71C thickness (.48") out to just beyond the raised

boss.

-

Here's one I haven't seen mentioned before;

the reverse gear switch is located about 22mm further back

on my F4W71B than on the FS5W71B or C. Since I didn't realize this until after I

chose the 4 speed bell housing to modify (it was already out of

the car), I had to drill and tap a new hole in the side of

the case to make my reverse switch work. If you're using a 5 speed 71B bell housing, this is not

a concern.

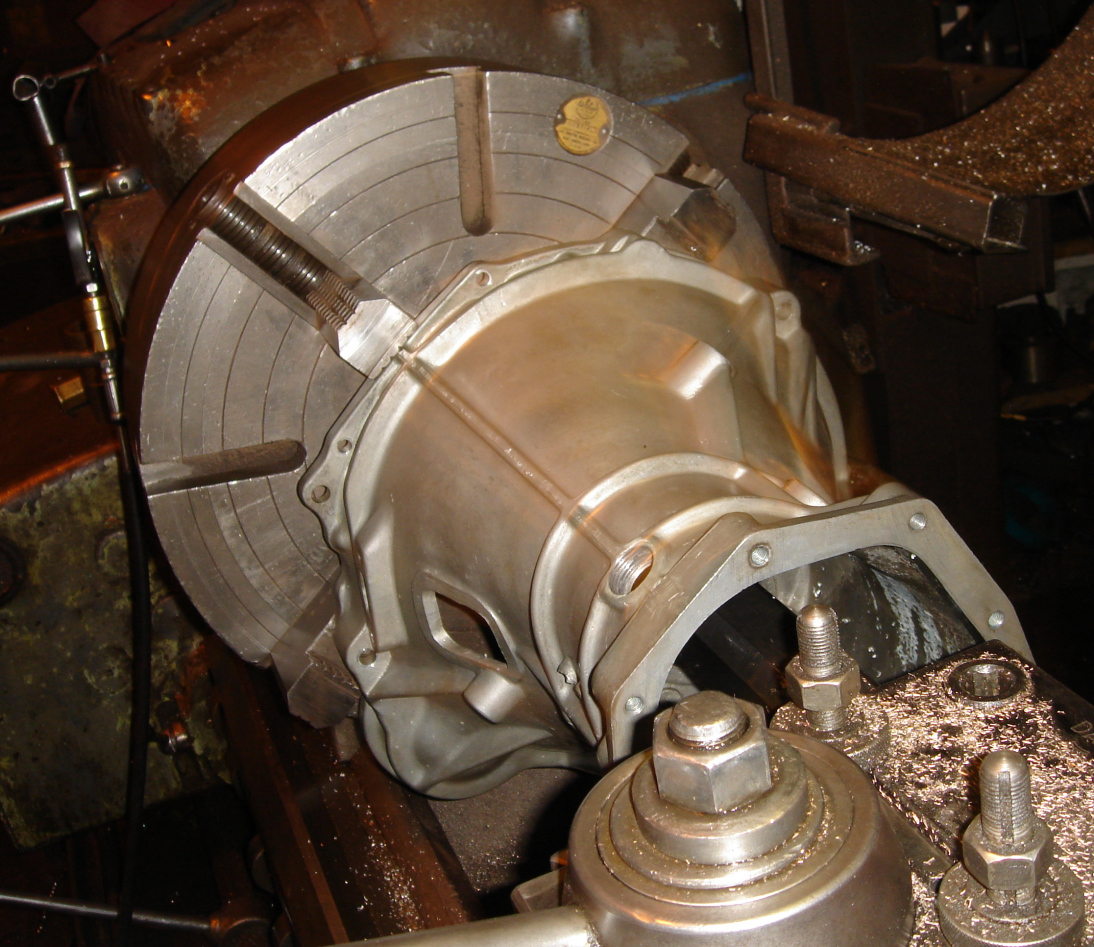

I had a machine shop in Knoxville do the work.

Ken at Newcomb Machine and Welding did this and

milled a new slot in the speedometer drive pinion sleeve for

$74 total. Incredible; I think he gave me a break because I'm a friend

of a friend.

F4W71B relocated

reverse

switch FS5W71B switch

FS5W71C

PAGE 1

PAGE 2 PAGE

3 PAGE 4