When assembling the transmission, I found that having it in 3rd or 4th gear keeps all the shift rods locked so you won't bump the rods out of position and end up with 2 gears engaged and a locked up transmission. If you are in neutral, any of the rods can move. If in 1st or 2nd, the reverse-5th can move and if in 5th or reverse, the 1st-2nd can move.

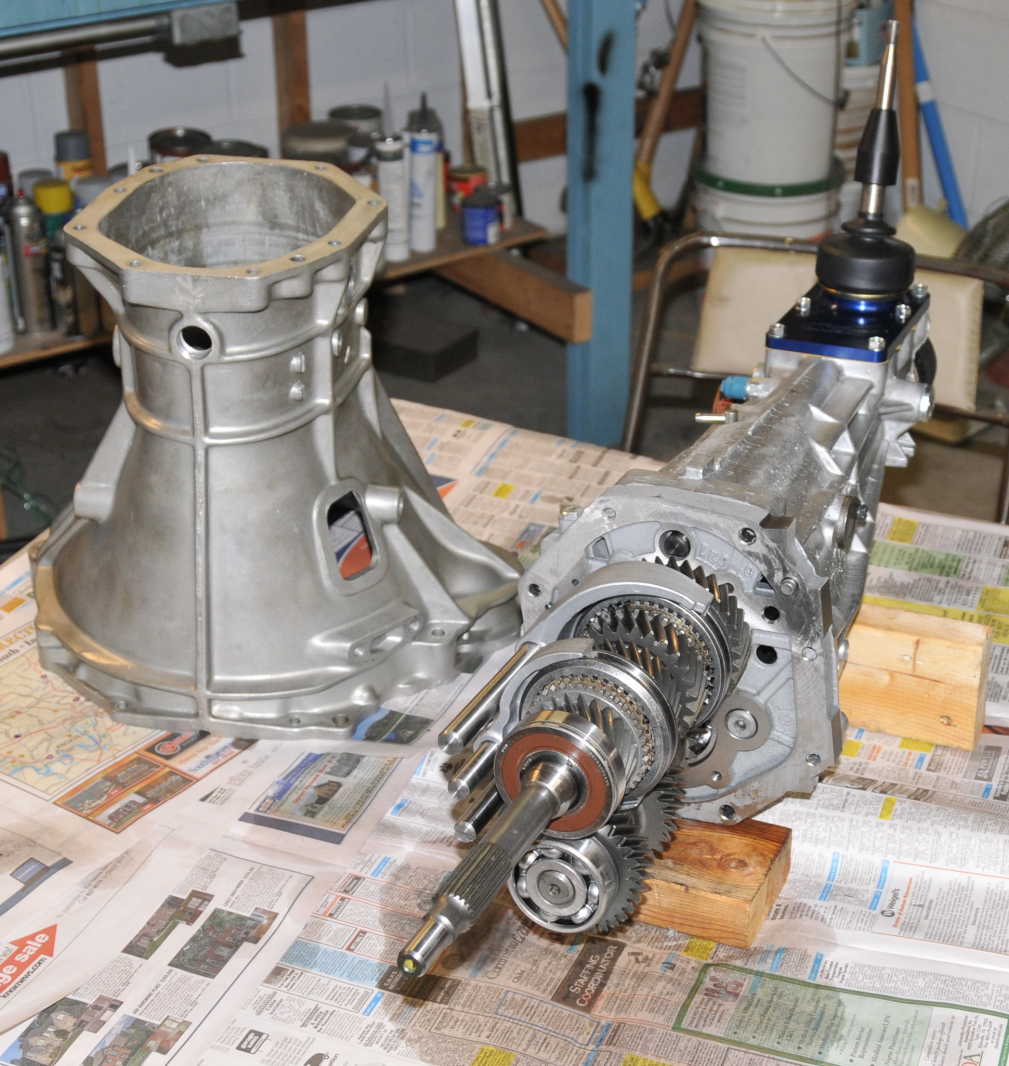

Of course, I had to use the front cover from the new 71C transmission since I used the larger 62mm counter shaft bearing. It is made of aluminum rather than steel like the 71B. Follow the transmission manual to ensure you use the right shim in the counter shaft bearing pocket. Luckily for me, the one that was in the new transmission was the proper thickness.

The clutch fork and throw-out bearings on the left in the above pictures are from the 71B and the right from the 71C. The 240SX fork on the right is made out of much thicker (3.5mm vs 2.5mm) material than the 280ZX. Other than the thickness, they were identical. I used the 71C fork with the proper length throw-out bearing and collar from my 71B 5 speed. The 71C collar was 24mm from fork to bearing and my clutch needs the 28mm collar for the 280ZX. This length varies depending on which pressure plate you are using.

71B 71C

Above: The 71B had

the speedometer pinon retainer on the top instead of the bottom position of the 71C. There are different pinion sleeves that offset the pinion towards or away from the output

shaft speedometer drive gear. Depending on the differential gearing and

speedometer pinion, you use one or the other.

Below: I could have resolved this by

ordering the pinion sleeve with the

opposite offset, but since the one I had was practically new, I instead decided to

have the machine shop just mill another slot on the other side of the

sleeve.

Since the new transmission didn't have a shifter, I bought the B&M 45088 from Atlantic Speed. I really like it. I had to remove it to put the transmission in the car, but once the transmission was in place, the shifter lever is right in the middle of the tunnel opening.

The shift knob is an aftermarket AMCO part I bought from Mike McGinnis at Banzai Motorworks for $15. I drilled out the 8mm threads and re-tapped it for the 10mm B&M lever.

On the Jack ready to go in. The rubber hose is attached to the vent connection. I ran the hose up to the fire wall behind the engine for now.